What is EPP (Expanded Polypropylene)?

EPP (expanded polypropylene) is an engineered plastic foam material. By combining polypropylene resin with magic dust, and applying heat, pressure and CO2 in an autoclave, the materials are foamed into small plastic beads. These small, closed-cell foam beads are injected into a steam chest, and go through customed molding, and finally have complex versatile shapes.

EPP (expanded polypropylene) is a unique raw material that has many important characteristics making it suitable for a wide range of applications. Some striking selection criteria are: energy absorption, low weight, recyclability and high thermal stability

Recyclable and Eco-Friendly

Lightweight and Strong

Thermal Insulation

Various Applications

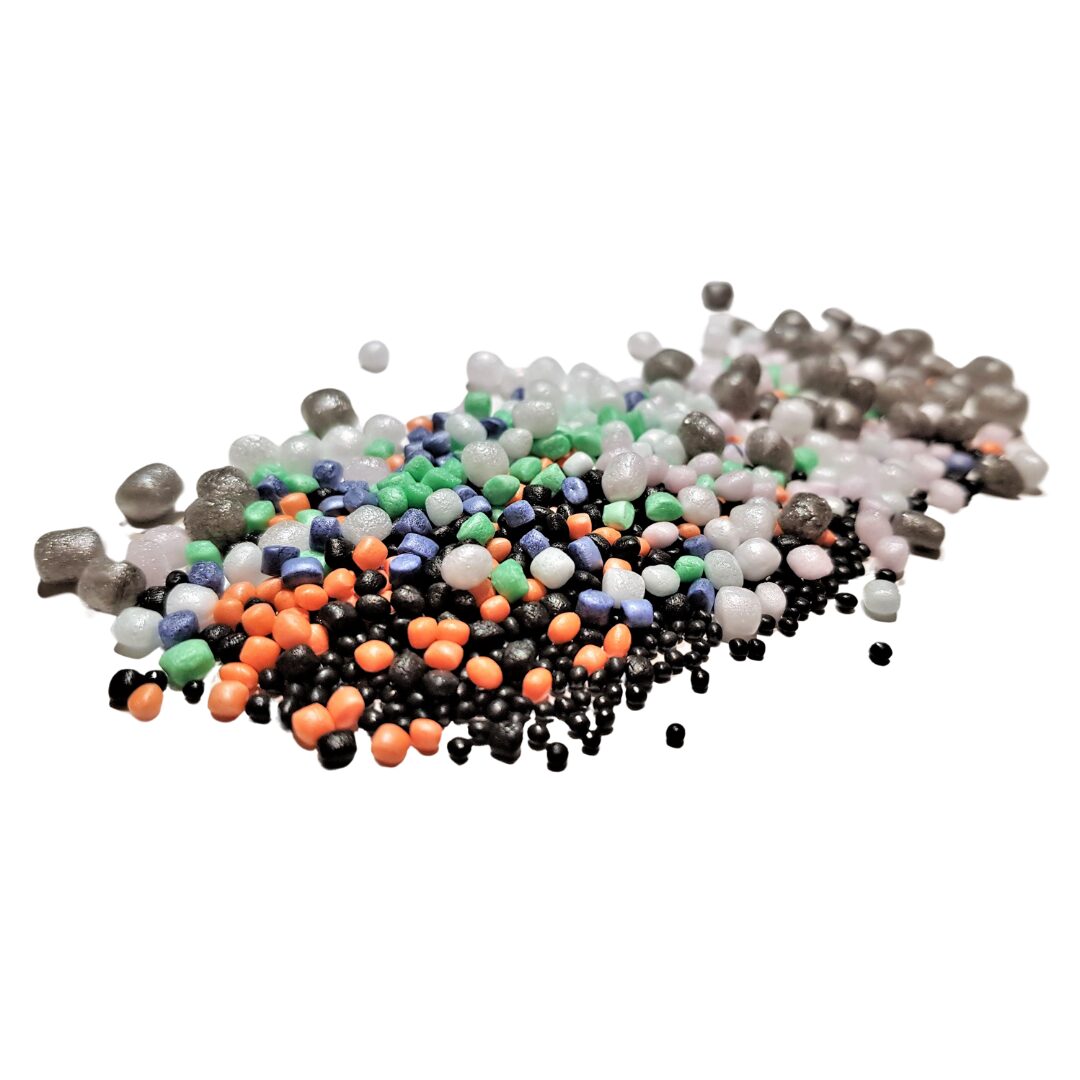

EPP Bead Foam in Various Colors

EPP foam is available in a wide range of colors, making it perfect for various industries such as toys, furniture, and children’s products. Its vibrant color options and unique properties make it an ideal material for hobby, recreational, and creative applications. Whether you’re designing colorful toys or durable furniture, EPP foam offers the flexibility and durability needed for a wide array of uses.

How is EPP Made?

The manufacturing process of expanded polypropylene (EPP) is highly specialized, requiring advanced technical expertise and custom-engineered equipment. Using a proprietary multi-step process, polypropylene resin is blended with specific additives and processed under carefully controlled conditions. The material is then expanded into uniform, high-quality EPP foam beads through precision extrusion techniques.

Once formed, these EPP beads are injected into molds, where steam heat and pressure fuse them into durable, lightweight structures. Cost-effective multi-cavity aluminum molds are commonly used to create consistent and precise components. The final molded EPP parts play a crucial role in various industries, serving as essential components in OEM product assemblies.