What is E-TPU (Expanded Thermoplastic Polyurethane)?

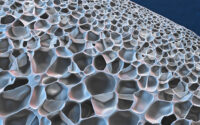

E-TPU, or Expanded Thermoplastic Polyurethane, is a foam material engineered from thermoplastic polyurethane beads that are expanded under heat and pressure. This process results in a highly resilient, closed-cell structure that retains the inherent properties of TPU—flexibility, durability, and resistance to wear—while significantly enhancing its energy-return capabilities.

Unlike traditional foams, E-TPU combines the softness and cushioning of foam with the robustness and elasticity of plastics, creating a material that is both lightweight and highly durable. This unique combination makes E-TPU an ideal choice for applications that require both comfort and performance, such as athletic footwear, protective sports gear, and ergonomic seating solutions.

Durability

Lightweight

Excellent Resistance

Eco-fiendly

E-TPU Elastic Principle

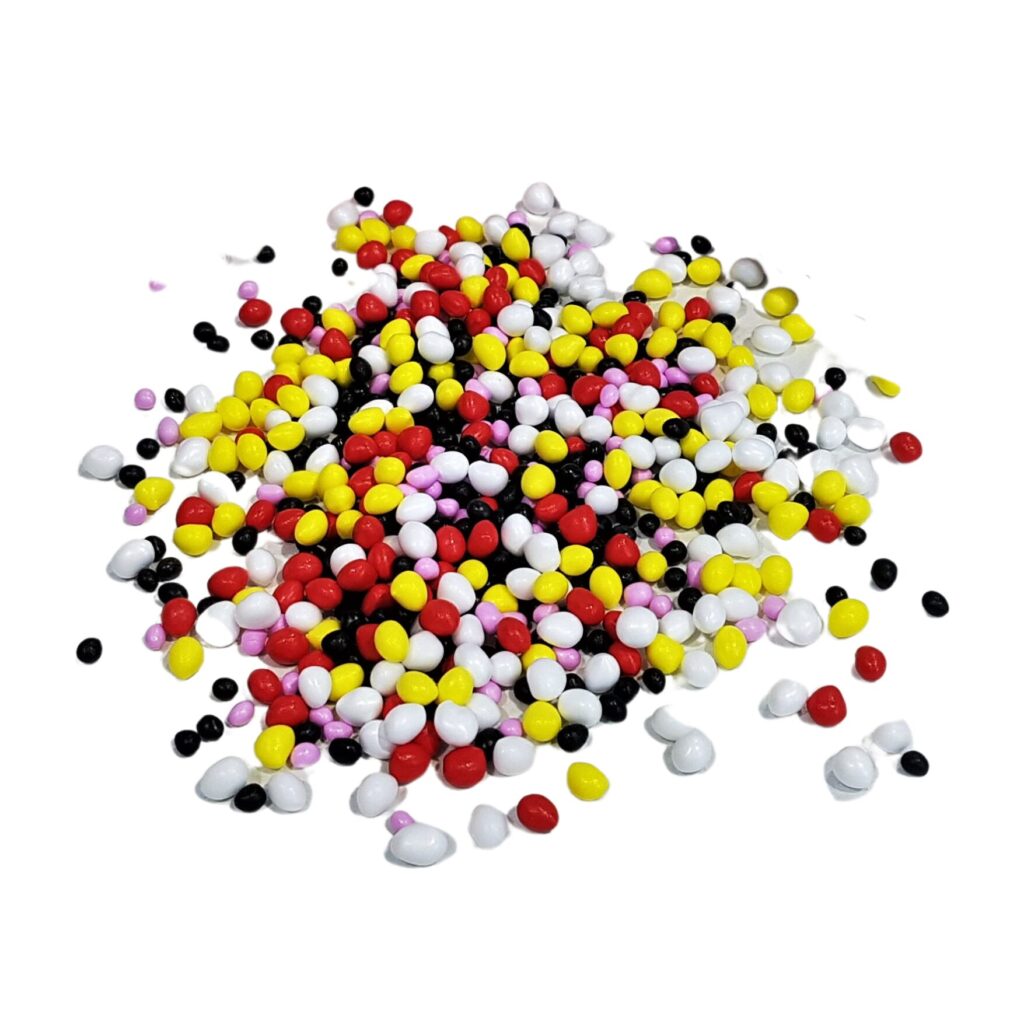

E-TPU polyurethane thermoplastic foamed granules (ETPU beads) are TPU (thermoplastic elastomer material) particles that expand like popcorn after undergoing a pre-treatment involving pressure heating. During this process, the original size of the particles, which is approximately 0.5 mm, increases in volume by a factor of 10, resulting in oval, non-crosslinked foamed particles of E-TPU containing micro-closed cells that resemble “popcorn”.

The ETPU beads are heated to a temperature of about 150 degrees to the softening point of TPU during the foaming process in the autoclave, and the CO2 blowing agent is impregnated into the soft segment (SS), causing the TPU to swell and hard segment (HS) crystal domain arrangement. It becomes the basic principle of having good elasticity.

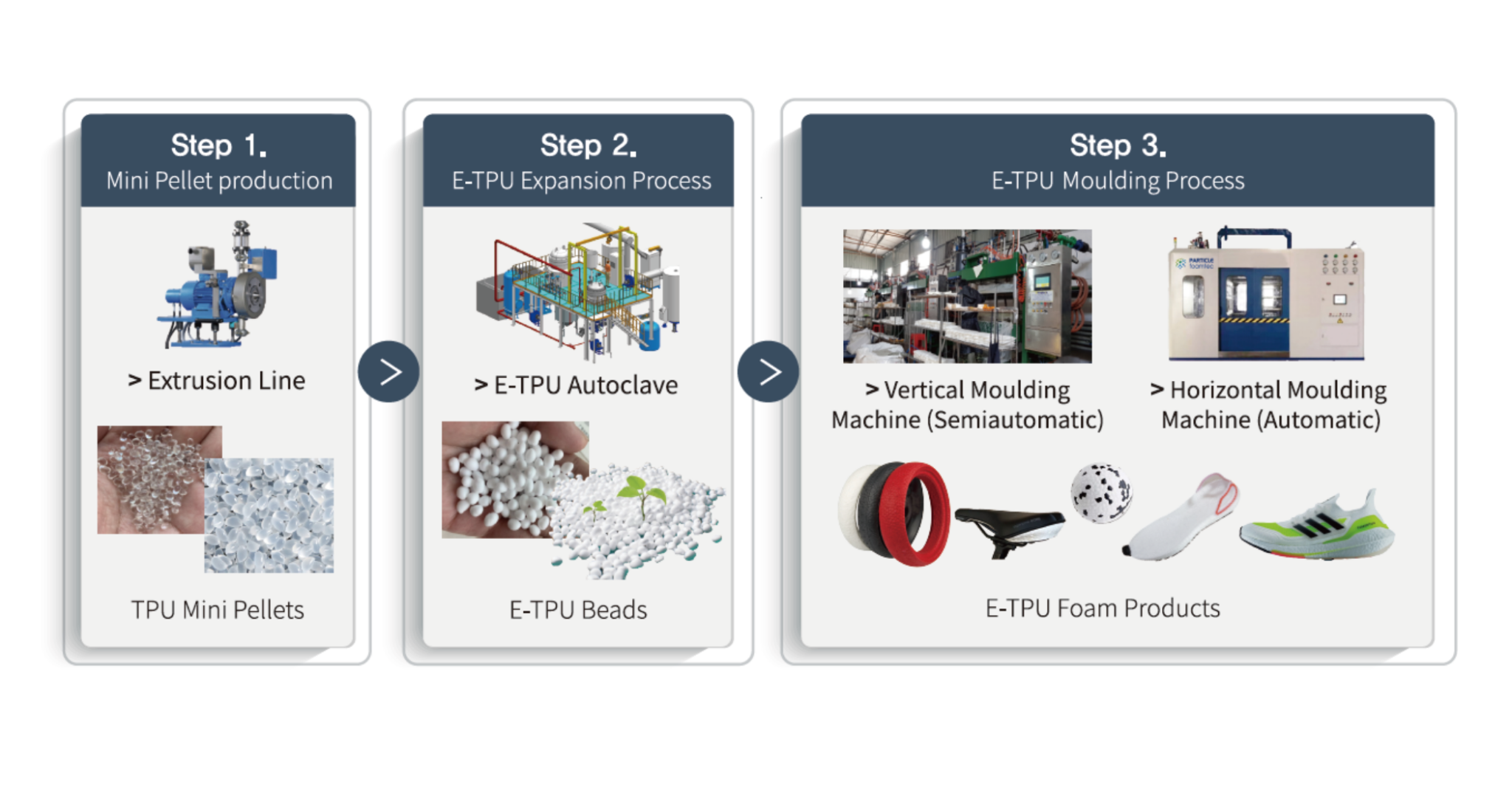

E-TPU Production Process

The E-TPU (Expanded Thermoplastic Polyurethane) production process begins with raw TPU granules, which are expanded using supercritical gas—typically steam or CO₂—under high pressure. This expansion forms lightweight, closed-cell foam beads that offer excellent elasticity, durability, and energy return.

After expansion, the beads go through a conditioning phase before being molded into various shapes using steam fusion technology. This step ensures strong bead bonding, creating high-performance materials used in sports shoes, automotive components, and cushioning applications. E-TPU manufacturing is also an eco-friendly process, minimizing material waste while enhancing product longevity, making it a popular choice for innovative industries.