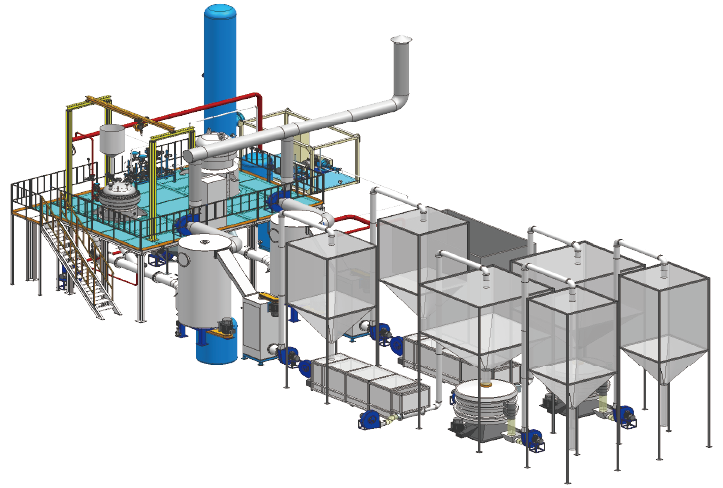

TURN-KEY SOLUTION OF AUTOCLAVE EPP BEADS PRODUCTION

EPP Beads Expansion System

First, EPP mini-pellets of about 1mg are made from the extursion process. Then the mini-pellets are placed in an autoclave at high temperature and high pressure to be impregnated with CO2 and expanded 5 to 30 times.

A higher expansion ration over 30-70 times, or even higher, can be obtained by using the steam pressure in the secondary foaming machine. On the other hand, PP has a very low melt strength, and it is very difficult to form cell walls. Therefore, expensive manufacturing facilities with very precise and professional control systems for making two-peak crystals in PP are required.

Digitalization of EPP Plant

We provide a turn-key smart factory that provides optimal foam processing conditions to stably and cost-effectively produce EPP foam beads by applying artificial intelligence (AI) to the recently digitized factrory in our autoclave-based EPP equipment.

SCADA typically consists of a combination of software and hardware such as PLCs and RTUs. The data are collected from PLCs and RTUs that communicate with plant floor equipment such as factory machines and sensors.

Collected data from the equipment are transferred to the next level like a control room, so that the operator can supervise PLC and RTU control by using HMI. The HMI is a screen which is a major element of the SCADA system to support communication between the operator and the system.